How to choose the off-the-shelf capacitor manufacturer?

How to Choose the Off-the-Shelf Capacitor Manufacturer

Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. Their importance cannot be overstated, as they are integral to the functionality of a wide range of devices, from consumer electronics to automotive systems. Given their significance, selecting the right manufacturer for off-the-shelf capacitors is essential for ensuring product reliability and performance. This article aims to guide you through the process of choosing a capacitor manufacturer, highlighting key considerations and best practices.

1. Understanding Capacitors

1.1 Definition and Functionality

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied, an electric field forms between the plates, allowing the capacitor to store energy. Capacitors can release this energy when needed, making them vital for various applications in electronic circuits.

1.2 Types of Capacitors

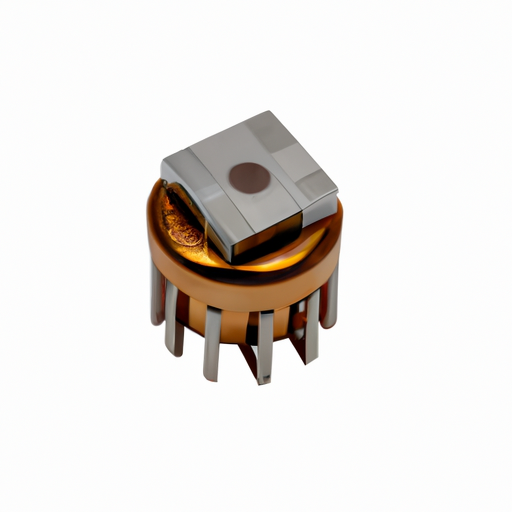

Capacitors come in various types, each suited for specific applications:

Ceramic Capacitors: Known for their small size and stability, ceramic capacitors are widely used in high-frequency applications.

Electrolytic Capacitors: These capacitors offer high capacitance values and are commonly used in power supply circuits.

Tantalum Capacitors: Known for their reliability and stability, tantalum capacitors are often used in critical applications.

Film Capacitors: These capacitors are known for their low loss and high voltage ratings, making them suitable for audio and power applications.

1.3 Applications of Capacitors

Capacitors find applications across various industries, including:

Consumer Electronics: Used in smartphones, televisions, and computers for energy storage and signal filtering.

Automotive: Essential for power management and signal processing in modern vehicles.

Telecommunications: Used in communication devices for signal coupling and decoupling.

2. Importance of Choosing the Right Manufacturer

2.1 Quality Assurance

The quality of capacitors directly impacts the overall performance of electronic devices. Poor-quality capacitors can lead to failures, affecting product reliability and customer satisfaction. Therefore, selecting a manufacturer with a strong commitment to quality assurance is crucial.

2.2 Reliability and Longevity

Capacitors are often subjected to varying environmental conditions and electrical stresses. Choosing a manufacturer known for producing durable and reliable capacitors ensures that your products will perform consistently over time, reducing the risk of failures and warranty claims.

2.3 Compliance with Standards

Adhering to industry standards and certifications, such as ISO and RoHS, is essential for ensuring that capacitors meet safety and environmental regulations. A reputable manufacturer will have the necessary certifications, providing peace of mind regarding product compliance.

3. Key Factors to Consider When Choosing a Manufacturer

3.1 Reputation and Experience

A manufacturer’s reputation and experience in the industry are critical indicators of their reliability. Look for manufacturers with a proven track record and positive reviews from customers. Established manufacturers are more likely to have the expertise needed to produce high-quality capacitors.

3.2 Product Range and Customization Options

Consider the range of capacitor types offered by the manufacturer. A diverse product range allows for flexibility in design and application. Additionally, check if the manufacturer provides customization options to meet specific project requirements.

3.3 Technical Support and Customer Service

Effective technical support and customer service are vital for addressing any issues that may arise during the design and production process. A manufacturer that offers responsive support can help troubleshoot problems and provide guidance on product selection.

3.4 Pricing and Value

While cost is an important factor, it should not be the sole consideration. Balance pricing with the quality and performance of the capacitors. Sometimes, investing in higher-quality components can lead to long-term savings by reducing failures and warranty claims.

3.5 Lead Times and Availability

Timely delivery is crucial for maintaining project schedules. Ensure that the manufacturer can meet your lead time requirements and has sufficient stock availability to fulfill orders promptly.

4. Evaluating Manufacturer Capabilities

4.1 Manufacturing Processes

Understanding the manufacturing processes used by the manufacturer can provide insights into the quality of their products. Look for manufacturers that employ advanced technologies and adhere to best practices in production.

4.2 Testing and Quality Control

Rigorous testing protocols and quality control measures are essential for ensuring that capacitors meet performance specifications. Inquire about the manufacturer’s testing procedures and certifications to ensure that their products undergo thorough evaluation.

4.3 Research and Development

A manufacturer’s commitment to research and development (R&D) is indicative of their dedication to innovation and product improvement. Manufacturers that invest in R&D are more likely to offer cutting-edge solutions and stay ahead of industry trends.

5. Gathering Information and Reviews

5.1 Online Research

Utilize online resources, such as manufacturer websites, forums, and social media, to gather information about potential manufacturers. Look for reviews and feedback from other customers to gain insights into their experiences.

5.2 Industry Publications and Trade Shows

Stay updated with industry news and trends by following relevant publications and attending trade shows. These events provide opportunities to meet manufacturers, learn about new products, and network with industry professionals.

5.3 Customer Testimonials and Case Studies

Customer testimonials and case studies can provide valuable insights into a manufacturer’s capabilities and reliability. Look for examples of successful projects that demonstrate the manufacturer’s ability to meet customer needs.

6. Making the Final Decision

6.1 Comparing Multiple Manufacturers

Create a comparison matrix based on the key factors discussed earlier. This matrix will help you evaluate and compare multiple manufacturers objectively, making it easier to identify the best fit for your needs.

6.2 Requesting Samples

Before making a bulk order, request samples from the shortlisted manufacturers. Testing samples allows you to assess the quality and performance of the capacitors in your specific application.

6.3 Building a Relationship

Establishing a long-term partnership with a manufacturer can lead to better collaboration and support. A strong relationship can also provide access to exclusive products and services, enhancing your overall experience.

Conclusion

Choosing the right off-the-shelf capacitor manufacturer is a critical decision that can significantly impact the success of your electronic products. By understanding the importance of quality, reliability, and compliance, and by considering key factors such as reputation, product range, and support, you can make an informed choice. Conduct thorough research, gather information, and evaluate multiple manufacturers to ensure that you select a partner that aligns with your needs. A good manufacturer can enhance your product's performance and reliability, ultimately contributing to your success in the competitive electronics market.

References

- [Understanding Capacitors: A Comprehensive Guide](https://www.electronics-tutorials.ws)

- [Industry Standards for Capacitors](https://www.iec.ch)

- [Capacitor Selection Guide](https://www.digikey.com)